Mixer Module

For many dosing applications, it is necessary to homogeneously mix different materials of varying bulk densities and flow characteristics. The mixer module 2l is designed for mounting under a dosing unit, where it will mechanically mix, for example a powder additive with virgin material. Further possible uses: Homogenous mixing of virgin material and regrind or with masterbatch or additives. motan has 3 versions available:

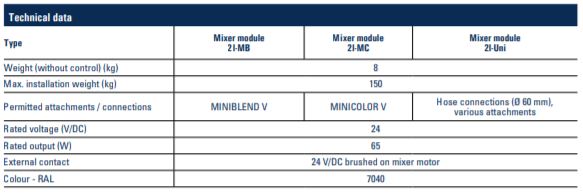

- Mixer module 2l-MB for MINIBLEND V

- Mixer module 2l-MC for MINICOLOR V / G

- Mixer module 2l-Uni for universal applications and third-party product

Mixer module 2l-MB As an extension for the MINIBLEND V additive dosing unit The mixer module 2l-MB can be easily installed under the MINIBLEND V additive dosing unit to typically mix non-free-flowing powders with virgin material.

Mixer module 2l-MC As an extension for the MINICOLOR V and MINICOLOR G additive dosing units The mixer module 2l-MC is installed directly under the MINICOLOR V or MINICOLOR G using a mounting flange and additional finger guard. A typical application is the dosing of virgin material with non-free-flowing regrinds.

Mixer module 2l-Uni The mechanical mixer for universal applications and third-party products With the mixer module 2l-Uni many other combinations are possible. For example, the module can be supplied with material loaders, proportioning valves or smaller drying bins with a material temperature up to max. 80 ° C. There is also the option to install a hose connection above and below the mixer module.

VOLU MC – Control for MB/MC/Uni Cost-effective solution for controlling the mixer module Modern microprocessor control with timer function and simple operation for all mixer modules 2l.