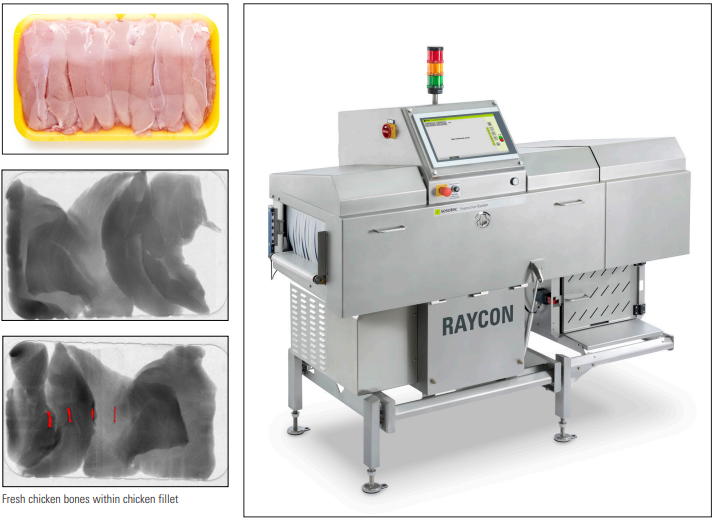

Metal Detection Food » X-ray Inspection System » Raycon D+

RAYCON D+ (Intelligent x-ray product inspection system for packaged products – End of line inspection)

The RAYCON D+ product inspection system detects all contaminants that due to their density, chemical composition, or mechanical dimensions absorb x-rays better than the surrounding product.

With its optional capability using Dual-Energy technology the performance for soft contaminants gets extremely improved for materials e.g. types of plastics (PVC, aso.), rubber, ceramics, stones, calcified bones and similar materials.

Detectability of different materials depending on their density

The RAYCON D+ product inspection system is characterised by the following

performance features:

The system comprises of the following main components:

(A) X-ray tube

This is where x-rays are electrically generated. The x-rays are emitted from the tube through a narrow slot and as a fan-shaped beam pass through the product to be inspected from back to front.

(B) X-ray beam

(C) Transport system

A PE flat belt (self guiding) uniformly transports the product to be inspected through the x-ray beam. This makes it possible to scan the

product line-by-line.

(D) Detector unit

The linear detector that is installed above the inspection aperture converts the arriving x-rays into an electrical signal from which a digital

x-ray image is created.

– 0,4 mm HD resolution

– 0,8 mm Dual Energy

(E) Industry-type PC

The PC is used to evaluate the images and to accurately control the reject systems.

Longer lifetime of core components by Intelligent Power Management (IPM)

- Automatic detection of product height

- Automatic power adjustment of the x-ray source

- Extended lifetime of x-ray source

- Increase of energy efficiency

- Maximum sensitivity without special settings

- Time savings during the learning process of the different products

Application variability

- The modular design allows adaptation to various applications

- Depending on machine configuration, foreign bodies are detected from 0,3 mm

- Modular principle enables fast, uncomplicated and cost-transparent upgrade

- Platform concept enables subsequent update

- Easy to clean due to hygienic design

- Tool-free belt change within 2 minutes

- HD (High Definition): Detects foreign bodies from 0,3 mm (e. g. stainless steel, steel, copper, glass, …)

- Dual Energy: Detects soft impurities from 2,0 mm (e. g. bones, rubber, …)

Surpassing detection requirements

- Surpasses the latest and most valid food regulations by up to 400%

- False reject rate (F.R.R.) below 0,01%

- The system detects products up to a conveying speed of 1 m/s

- Maximum throughput is 250 pieces per minute

Increased ease of use

- The 15 “HD touch display in 16:9 format offers a high resolution for excellent picture quality

- No special operating knowledge is necessary

- Automatic recognition of the product packaging by the edge filter

- Minimizing the frequency of false rejects and product wastage

- Automatic detection of the x-ray source lifetime and early warning by the system

- Warranty extension from 3 to 5 years through the optional service package

Technology comparison

High resolution vs. Dual Energy

Sensitivity:

Conventional systems RAYCON D+

30% found foreign bodies 100% found foreign bodies

Sliced bacon with 0,3 mm stainless steel impurities

Conventional systems RAYCON D+ Dual Energy

0% found foreign bodies 100% found foreign bodies

Noodles with glass splinter 2 mm x 3 mm (W x L)