RAPID 5000

Description

Metal Detector for Free-Fall Applications

• Metal detector for the inspection of powdery and fine-grained bulk materials

• This metal detector can Detects magnetic and non-magnetic metal contaminations

• This metal detector Separation by way of stainless-steel reject flap

• This metal detector is Hygienic design without any corners and edges in the separation unit

• This metal detector Complies with IFS and HACCP

• Separation unit and product-contacting metal parts completely made of stainless steel 1.4301 (AISI 304)

• Low mounting height guarantees easy integration of the metal detector in existing pipe system

• Separate detection and separation units: the free-fall metal detector height can be adapted on site & the position of the reject outlet can be swiveled to match the position of the collecting container

• Quick and minimum-effort installation of the metal detector due to standard Jacob connection system

• Auto-learn function with metal detector compensation for optimal adaptation to the intrinsic conductivity of the product to be inspected

• This metal detector can Increased interference immunity to electromagnetic pollution and vibration

• Metal detector include Highest scanning sensitivity for all metals

Function of The Metal Detector

The RAPID 5000 metal detector is used for the inspection of bulk materials in free-fall conveyor pipes. It detects all magnetic and non-magnetic metal contaminations (steel, stainless steel, aluminum, …) – even if such contaminations are embedded in the product. Metal contaminations are rejected by means of the separation unit (“Quick Flap”).

The RAPID 5000 metal detector primarily is used in industries with very high hygienic demands.

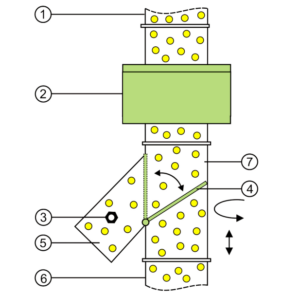

Function chart

- Infeed

- Detection coil

- Metal contamination

- Separation flap

- Waste rejection

- Material outlet

- Separation unit (turn able, removable)

Applications of The Metal Detector

• Incoming inspection (product purity and machine protection) of raw spices, ingredients, raw materials, etc. Prior to the processing machine (e.g., Mill).

• Quality inspection (product purity) of herbs, tea, spices, chemical additives (e.g., Ascorbic acid, surfactants), etc. Directly before filling in big bags and silos.

• Quality inspection of milk powder, flour, sugar, etc. Directly before a bag-forming, filling, and sealing machine.

GENIUS ONE Control Unit

• Metal detector include Highest sensitivity for all metals (2-channel technology)

• Digital signal processing and quartz-stable search frequency

• State-of-the-art microprocessor technology with self-monitoring, auto-balancing, and temperature compensation

• Product compensation with auto-learn function

• Multi-product memory Password protection / access protection

• Special EMC combi filter for suppressing external interference

Typical Fields of Application for This Metal Detector

• Pharmaceutical industry

• Chemical industry

• Food industry

Advantages of The Metal Detector:

• Versatile metal detection: the metal detector can identify both magnetic and non-magnetic metal contaminations in various materials.

• Efficient separation: metal detector utilizes a stainless-steel reject flap for effective removal of detected contaminants from bulk materials.

• Hygienic design: the metal detector is designed without corners and edges in the separation unit, ensuring cleanliness and suitability for sensitive environments like food production. The use of stainless steel (1.4301 or aisi 304) for the separation unit and product-contacting metal parts supports hygienic standards.

• Compliance with standards: the metal detector complies with ifs and haccp, meeting rigorous quality and safety standards in the food industry.

• Adaptable integration: with a low mounting height, metal detector easily integrates into existing pipe systems. Separate detection and separation units allow flexibility in adjusting free-fall height and positioning the reject outlet to match the collecting container.

• Ease of installation: the metal detector features quick and straightforward installation with the standard jacob connection system.

• Auto-learn function: the metal detector includes an auto-learn function with product compensation, adapting to the intrinsic conductivity of the specific product being inspected for accurate metal detection without manual adjustments.

• Interference immunity: the metal detector has increased interference immunity to electromagnetic pollution and vibration, ensuring reliable operation in challenging industrial environments.

• High sensitivity: the metal detector offers the highest scanning sensitivity for all metals, ensuring the detection of even small metal contaminants for comprehensive quality control.