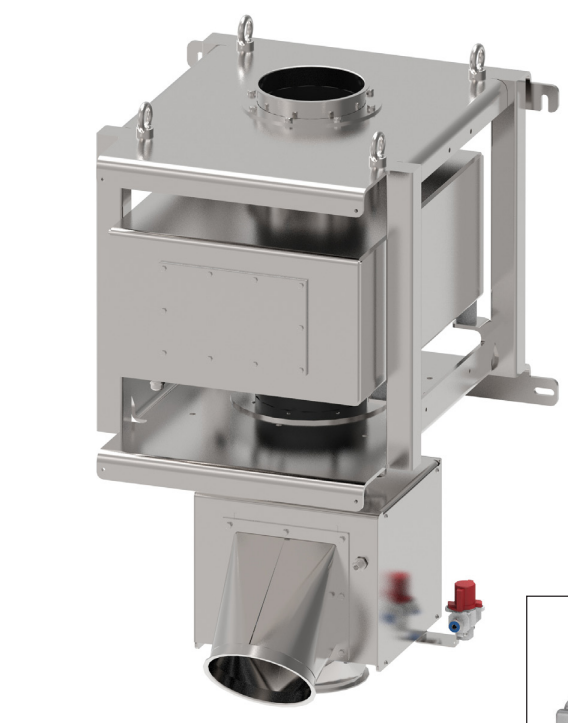

RAPID 4000

Description

Metal detector for Free-Fall Applications

• Metal detector will Detects and separates magnetic and non-magnetic metal contamination, even when enclosed in product

• Metal detector can Reduces expensive machinery failure and minimizes production downtime

• Ensures product quality with metal detector

• Prevents customer complaints by using metal detector

• Break even within a very short period of time when you are using metal detector

• Separated detection and separation units of metal detector:

– Free-fall height can be individually adjusted on site

– Position of waste reject unit can be turned to match position of collecting tray

• Learn automatic or manual product compensation (not pre-adjusted) to improve adaption to product and conveyor belt conductivity

• Pre-installed parameters simplify operation in this metal detector

• This metal detector is High scanning sensitivity to all metals

• Minimal waste through “Quick-Flap” rejection system that included in this metal detector

• Low installation height, the metal detector can be easily fitted into existing pipeline systems

• Standard adaptor system Jacob-Rohrbau (= Jacob pipe system) enables quick, hassle-free installation

• Metal detector Increased signal-to-noise-ratio towards electromagnetic pollution and vibrations

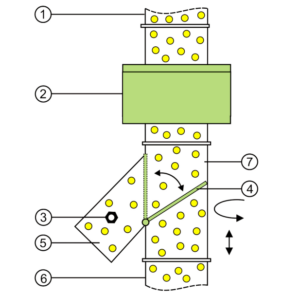

Function chart

- Infeed

- Detection coil

- Metal contamination

- Separation flap

- Waste rejection

- Material outlet

- Separation unit (turn able, removable)

Options/Accessories of The Metal detector for Free-Fall Applications:

• Optical and acoustic signal system

• Feed hoper and filler neck

• Digital incident counter

• Air pressure monitoring

• Magnet system enables pre-rejection of iron

• High temperature resistant

• Special design for abrasive bulk goods

• Removable control unit

Applications of The Metal detector for Free-Fall Applications:

• Machinery protection for extruders, blow molding machines, fine grinding mills, after dose units (rotary valve, vibro chamfer)

• Quality control e. G. For pre-delivery inspection of new goods, granulate, furnish, reclaim before octabins, big-bag stations, dryers and packing stations

Typical Application Areas Can Use the Metal detector for Free-Fall Applications:

• Plastics industry, in-house recycling

• Recycling industry

• Wood industry

• Chemical industry

• Food industry

• Feeding stuff industry

Scope of Delivery for The Metal detector for Free-Fall Applications:

• Metal detector with separated detection and separation units (installation via Jacob fastener)

• Control Unit GENIUS ONE

Benefits of Metal detector for Free-Fall Applications:

Contamination detection and separation: metal detector enhances product quality by eliminating potential hazards and ensures compliance with safety standards.

Machinery protection and downtime reduction: metal detector protects expensive machinery, increases operational efficiency, and reduces the likelihood of unexpected breakdowns.

Quality assurance: metal detector reduces the likelihood of defects and customer complaints, enhancing the reputation of the brand.

Rapid return on investment: companies can realize cost savings and improved profitability in a relatively short time frame using this metal detector.

Customizable and adaptive design: metal detector enhances flexibility, making the metal detector adaptable to various products and conveyor belt systems.

Ease of operation: metal detector reduces the learning curve for operators, streamlining the manufacturing process.

High sensitivity and minimal waste: the “quick-flap” rejection system minimizes waste, optimizing the efficiency of the production process using metal detector.

Easy installation and integration: metal detector reduces installation time and costs, enabling a hassle-free implementation of the metal detector into the production line.

Reduced interference: metal detector increased signal-to-noise ratio towards electromagnetic pollution and vibrations enhance the accuracy of metal detection.