GLS

Description

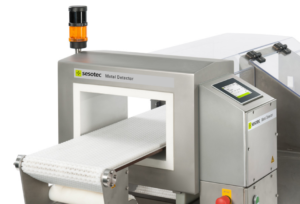

Metal Detector for Installation on Conveyor Belts:

- This metal detector will Detects magnetic and non-magnetic metal contamination, even when enclosed in product

- Reduces expensive machinery failure and minimize production downtime

- Ensures product quality with metal detector

- Metal detector can Prevents customer complaints

- Break even within a very short period of time

- Optimal detection and highest precision of metal detection in all areas of the detection head using this metal detector

- Password-protected system log and menu-controlled validation system for HACCP, IFS, BRC conform quality monitoring

- Offers perfect adaptability to customer-specific requirements (200 different coil sizes for the closed coil system to choose from)

- This metal detector Available with multi-frequency technology

- Compact design through highly reduced size of metal-free zone (RZ-technology)

- Design in stainless steel with protection class IP 65 (higher protection grade on request)

- Can be delivered as a complete unit with conveyor and separation system

Function of Metal Detector:

The metal detector GLS with closed detection head and rectangular opening is mainly used to analyze piece goods and bulk material on conveyors or material chutes. It detects all magnetic and non-magnetic metal contaminations (steel, stainless steel, aluminum) – even if enclosed in the product. On detection of metal, a signal device and a separation system can be activated or a signal can be sent to process controlling.

The closed design of the detector has the advantage to guarantee high metal sensibility within the detection head. Consequently, this metal detector is mainly used for highly precise detection tasks (e. g. in the food industry). GLS Metal detectors can be combined with numerous separation systems (air blast, pusher, etc.).

Additional Features of Metal Detector:

– Individual size adaption to customer specific requirements

– Can be installed on all levels

– High mechanical stability and noise immunity

– Largely insensitive to vibrations, hits and temperature change

Applications of Metal Detector:

– Quality control for incoming and outgoing goods in the food industry according to IFS, BRC, HACCP, ISO 22000 etc.

– Machinery protection for fruit and vegetable processing

Advantages of Metal Detector:

– Detection of Various Metal Types: The metal detector can detect both magnetic and non-magnetic metal contamination, including steel, stainless steel, and aluminum. This broad detection capability ensures comprehensive safety.

– High Precision: The closed detection of metal detector head design ensures high metal sensitivity, making it suitable for applications that require precise metal detection, especially in the food industry.

– Reduction in Machinery Failure: By detecting metal contaminants early in the production process using metal detector, the equipment helps prevent metal-related damage to machinery. This reduces expensive repairs and production downtime.

– Ensures Product Quality: Metal contamination in products can lead to quality issues and safety concerns. The metal detector helps maintain product quality by preventing contaminated items from reaching the market.

– Prevents Customer Complaints: Detecting and removing metal contaminants from products before they reach consumers minimizes the risk of customer complaints, product recalls, and potential harm when use metal detector.

– Quick Return on Investment (ROI): The ability to prevent machinery damage, ensure product quality, and prevent customer complaints can lead to a rapid return on investment, making it a cost-effective solution with our metal detector.

– Customization: The metal detector offers adaptability to customer-specific requirements, including the choice of different coil sizes for the closed coil system. This flexibility is valuable for various industries and applications.

– Multi-Frequency Technology: Availability of multi-frequency technology in metal detector allows for even more precise and versatile metal detection, adapting to different product types and conveyor belt materials.

– Hygienic Design: The stainless-steel design of metal detector with protection class IP 65 ensures hygiene and durability, making it suitable for use in industries like food and pharmaceuticals.

– Comprehensive Compliance: The password-protected metal detector system log and menu-controlled validation system make it suitable for compliance with quality monitoring standards such as HACCP, IFS, BRC, and ISO 22000, which are crucial in regulated industries.

Importance and Benefits of Metal Detector:

– Product Safety: The metal detector is essential for ensuring the safety of end consumers by preventing metal contamination in products, particularly in the food and pharmaceutical industries.

– Quality Control: metal detector plays a vital role in quality control by consistently identifying and removing metal contaminants, thus maintaining product integrity and brand reputation.

– Production Efficiency: By reducing machinery failure and minimizing downtime, the metal detector enhances production efficiency and reduces operational costs.

– Regulatory Compliance: The ability to conform to industry-specific quality and safety standards is crucial for regulatory compliance and meeting the requirements of organizations like IFS, BRC, HACCP, and ISO 22000 when using metal detector.

– Customization: The metal detector adaptability and customizable options cater to the specific needs of various industries and applications, providing flexibility and versatility.

– Versatility: The metal detector can be used in a wide range of industries beyond food, including chemical, pharmaceutical, packaging, and textile, making it a versatile solution for contamination detection.

Typical Fields of Application for Metal Detector:

– Food industry

– Chemical industry

– Pharmaceutical industry

– Packaging industry

– Textile industry

Complete systems

The complete systems UNICON+ and VARICON+ – consisting of GLS metal detector, conveyor and partially with separation unit – can easily be integrated into production lines. Due to the optimal coordination of all components, complete systems guarantee highest standards for security and detection precision.

Scope of delivery

- Two-channel, stainless steel metal detection coil with tunnel opening

- Equipped with control unit GENIUS ONE as standard