PROTECTOR (Metal separator for extruders, injection moulding and blow moulding machines)

Function

Function chart

Scope of delivery

Options/ accessories

Typical fields of application

Used for

Function

Small metal particles in the plastic melting process often result in costly breakdowns of injection moulders, extruders and blow moulders. The quantity of such metal contaminants increases throughout the processing of regranulates and grinding stock. As a result, clogged nozzles, filters and hot channel systems can lead to production downtime and delayed delivery.

The metal separator PROTECTOR is installed directly over the feeder of an injection moulder, an extruder or a blow moulder.

It detects all magnetic and non-magnetic metal contaminants (steel, stainless steel, aluminium, etc.) – even when they are enclosed in the product. Metal contaminants are ejected via the “Quick-Flap” separation unit.

>

>

>

>

Installation example: Metal separator PROTECTOR installed overthe feeder of an injection

moulding machine (old version)(old version)

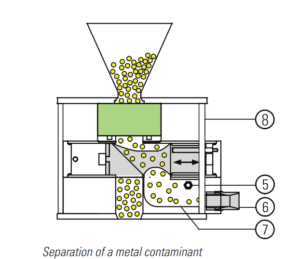

Function chart

- Material hopper

- Detection coil

- Separation unit

- Converting machine

- Metal contamination

- Venturi nozzle

- Reject outle

- Reinforcing framework

Scope of delivery

Metal separator with remote Control Unit PRIMUS+

Options/ accessories

Typical fields of application

- Plastics industry

Used for