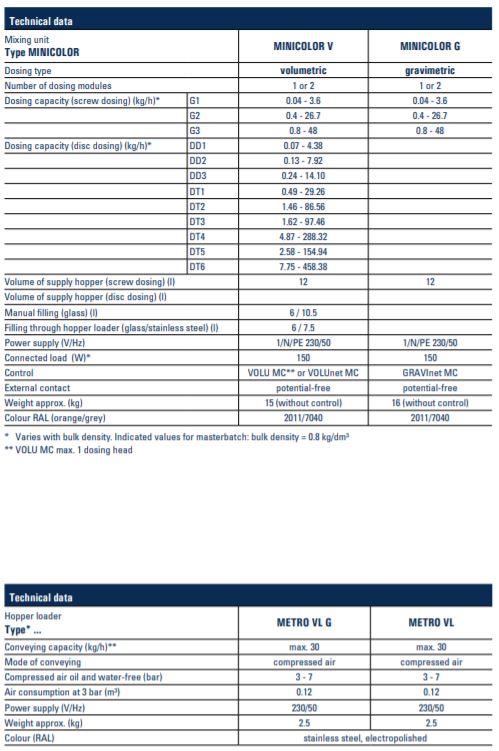

Plastic Manufacturing Processing » Dosing & Mixing » Volumetric dosing mixing unit » MINICOLOR V

MINICOLOR V

The demand for excellent mixing quality and consistently accurate dosing is a must when combining additives to the virgin material at the processing machine.

The gravimetric MINICOLOR V dosing and mixing units meet and exceed these requirements. Mounted at the feed throat of the plastics processing machine, the units require very little space.

Depending on need and requirement, screw or disc dosing modules can be installed at the mixing neck. Disc dosing is ideal for translucent and opaque parts as well as for dosing very small quantities.

The volumetric dosing and mixing unit MINICOLOR V meets and exceeds these requirements. Mounted between the machine hopper and the feed throat of the plastics processing machine, it requires very little space.

MINICOLOR V/METRO VL

VOLUMETRIC ADDITIVE DOSING UNITS

A stainless steel cruciform in the mixing neck divides the free-flowing main component into two streams of material. They flow together with the simultaneously dosed additives at the feed inlet producing a homogeneous mixture.

Depending on need and requirement, screw or disc dosing units can be installed at the mixing neck. Disc dosing is ideal for translucent and opaque parts as well as for dosing very small quantities.

The additive supply hopper can be filled easily by hand or with a METRO VL Venturi material loader.