Plastic Manufacturing Processing » Conveying » Granulate Conveying » METROLINK

METROLINK

Motan’s material selection stations assure that every desired connection of a material to a processing machine in your production process can be made quickly and reliably without contamination. Fixed pipe connections throughout the whole production process until the next material change ensures maximum security.

METROLINK: the most advanced fully automatic material selection and distribution system.

Description

Description

Fully automatic

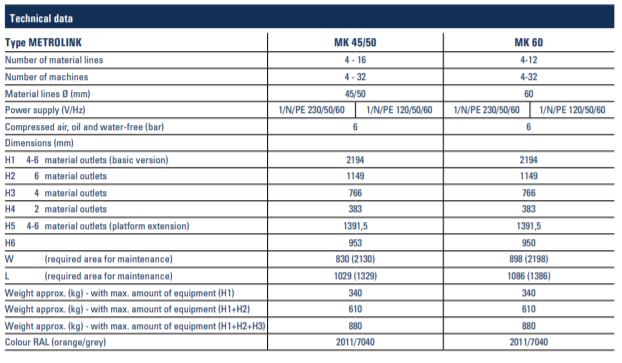

METROLINK assures that every desired connection of a material to a processing machine in your production process is made automatically and without any chance of cross contamination. One METROLINK tower can manage up to 16 materials being conveyed to 32 machines – all this with a floor space footprint of under 1m2.

Wear resistant solutions

When conveying very abrasive materials, for example glass-reinforced polyamides, it is important that the material selection station is designed to withstand wear. One solution is to use glass material feed lines and bends. motan’s glass bends are PU coated and earthed – making them shatter proof and eliminating the danger of static.

Pipework

Fixed pipe connections throughout the whole production process until the next material change ensures maximum security and long service life. METROLINK has no flexible hoses and there are no switching operations during normal conveying.

Optimised conveying

Because of the fixed pipe connections, system throughputs can be increased and several machine lines can be parallel fed with material at the same time. Controls METROLINK can be fully integrated into the motan CONTROLnet world or operate as stand-alone units with a 5.7” colour touch panel.

METROLINK assures that every desired connection of a material to a processing machine in your production process is made automatically and without any chance of cross contamination. One METROLINK tower can manage up to 16 materials being conveyed to 32 machines – all this with a floor space footprint of under 1m2.

Wear resistant solutions

When conveying very abrasive materials, for example glass-reinforced polyamides, it is important that the material selection station is designed to withstand wear. One solution is to use glass material feed lines and bends. motan’s glass bends are PU coated and earthed – making them shatter proof and eliminating the danger of static.

Pipework

Fixed pipe connections throughout the whole production process until the next material change ensures maximum security and long service life. METROLINK has no flexible hoses and there are no switching operations during normal conveying.

Optimised conveying

Because of the fixed pipe connections, system throughputs can be increased and several machine lines can be parallel fed with material at the same time. Controls METROLINK can be fully integrated into the motan CONTROLnet world or operate as stand-alone units with a 5.7” colour touch panel.