X-ray Inspection of Metal Detection Systems

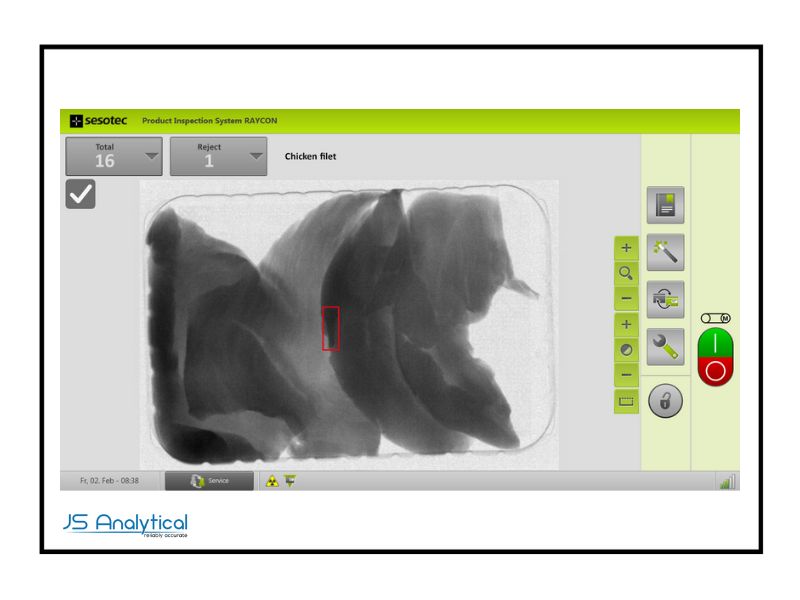

X-ray systems metal detection in the food processing sector depends on a computer system to detect foreign items.

One of its key benefits is:

X-ray inspection system’s ability to identify materials like glass, rock, bone, plastic, and rubber that metal detections are unable to. Products having metal-based packaging, such as foil, metallic film, or aluminium, can also be screened using X-ray machines. Metal detection cannot be used with metal-based packaging if your products include any metallic elements. But an x-ray inspection system of metal detection will be a better fit for your production line.

X-ray inspection systems of metal detection’s most challenging task are separating contaminants from the product or packaging. The contamination has to sufficiently contrast from the product for an x-ray inspection equipment. To clarify, identify it in a greyscale picture because a material’s density affects this contrast. Low-density things like hair, paper, or fabric are more difficult for X-ray devices to detect. False positive results may be expensive. Therefore it’s advisable to thoroughly test your items to see if an X-ray system can find impurities in them.

Click The Link Below for More Information Regarding X-Ray Inspection Systems for the Food Industry:

X-Ray Inspection System for the Food Industry

![]()