How to Measure Colour for your Business

Having trouble with visual colour checking? Need accurate colour reading?

Before colour is painted, printed and produced, manufacturers have to ensure that colour is monitored and accessed during the design stage, the formulation & production process and finally during the quality control process. Which determines the overall outlook on the products while attracting customers…

After the product assembly, final quality checks are done to identify and if needed, fix the colour issue. This is less expensive than doing rework on your goods after a rejection call.

There are many ways to identify & categorise colours, which includes:

After the product assembly, final quality checks are done to identify and if needed, fix the colour issue. This is less expensive than doing rework on your goods after a rejection call.

There are many ways to identify & categorise colours, which includes:

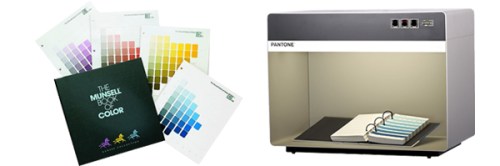

Visually / Manually

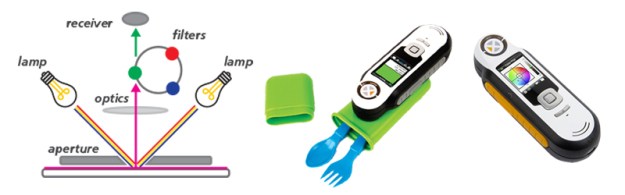

Using Colour meter or Colourimeter

Using a Spectrophotometer

Applicable industry:

Each filling machine comes with various features for industries like food, pharmaceutical, chemical, oil, petroleum, and many others to fit into their specific requirements to cater for :

Brought to you by, JS Analytical Sdn Bhd (1094207-V)

NEED CONSULTATION ON COLOUR MEASURING EQUIPMENT?

NEED CONSULTATION ON COLOUR MEASURING EQUIPMENT?

View our list of Colour Measuring Systems, visit our website

Reach out to our expert today for a professional recommendation.Elton Wong, Product Specialist,

+6012-292 2371, sales11@jsanalytikal.com cc marketing@obsnap.com